DQA-EP Fully Automatic Brazing Machine For Diamond Saw Blade

Our DQA-EP series is high intelligen and precision machine in diamond saw blade brazing. It using our innovative brazing system to make the brazing more accurate,stable and efficient.

- Haineng

- Fujian

- 10 PCS Per Month

- Information

Product Introduction

n Our DQA-EP series is high intelligen and precision machine in diamond saw blade brazing. It using our innovative brazing system to make the brazing more accurate,stable and efficient. Our fully automatic brazing machine is customized product which has multiple choices for different saw blade brazing. Customized project including automatic level,brazing range and brazing function,etc.

n Features

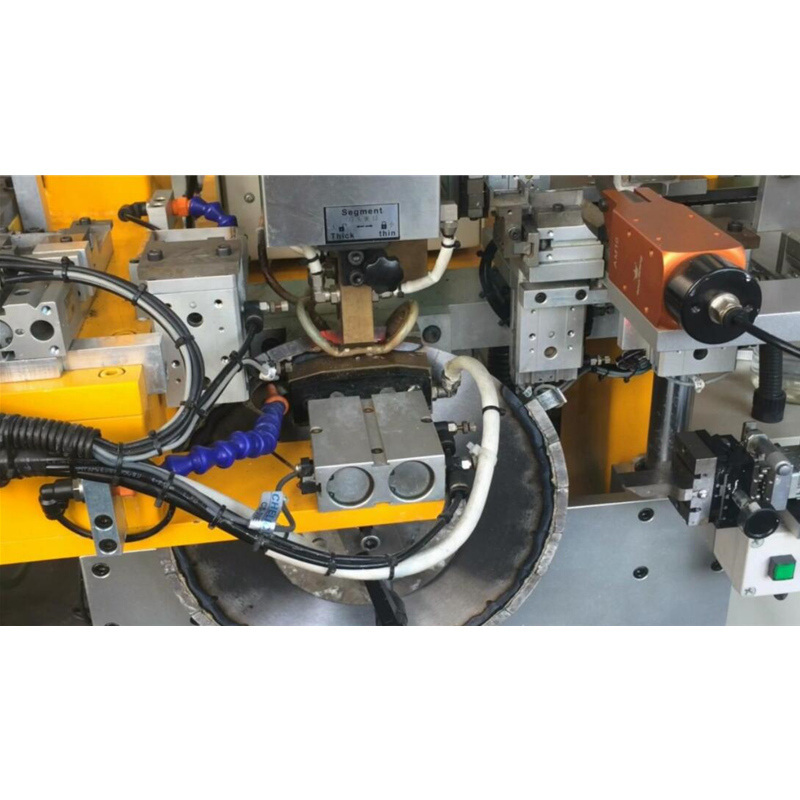

DQA-EP series machine has our patented SACCF system(Solder Automatic Cutting Correcting Feeding system) which guarantee 100% successful feeding rate for all kinds diamond saw blade.

We use gapless brazing hand and 0.01mm minimum unit fine tuning system combine with segment automatic centring system(optional)make the brazing easy and accurate. Machine has Saw blade automatic reload system(optional), it is optimal solution to save labor cost in volume-produce. Moreover machine has high tolerance design, as it can good working in segment edge<1.7mm and dimension error<30%.A variety of brazing mode selection make this machine can suit for all kind diamond saw blade, such as stone cutting blade, ceramic cutting blade or jewel cutting blade. Moreover this machine does not require high standard segment and brazing material due to the innovative design, so this machine can suit for multiple production condition and cost control requirement.

■ Configuration

1.Segment automatic picking & fixing system. Machine can automatic pick up the segment and fix to the brazing position.

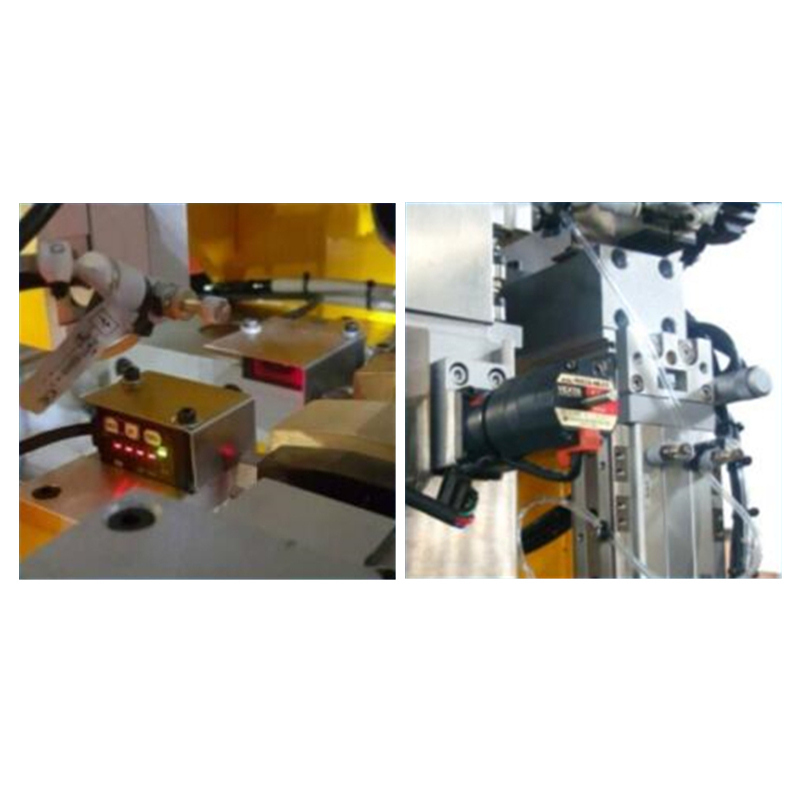

2.Sliver solder automatic cutting Correcting & sending system.Operator can set the length of the solder in the touch screen, then machine will automatic cut off the solder and sent to the welding position. Very accurate and convenience. (Requirement:solder thickness 0.1-0.4mm width>2.2mm)

3.Automatic soldering flux feeding system.Sliver solder and flux feeding are both independent, so they will not influence each other.

4.Laser positioning system

5.Dynamoelectric automatic segments separating system.

6.Ceramic clip protection function.

7.Error automatic stop & display system

8.Smoke cleaning system

9.Fan cooling system

Technical Parameters

|

Model |

DQA60-EP |

DQA40-EP |

DQA80-EP |

DQA100-EP |

|

|

Brazing Diameter(mm) |

φ180~φ350 |

φ300~φ550 |

φ170~φ400 |

φ300~φ800 |

φ350~φ1100 |

|

Welding Error(Verticality)(mm) |

≤±0.03 |

≤±0.05 |

≤±0.02 |

≤±0.03 |

≤±0.03 |

|

Welding Error( Linearize)(mm) |

≤±0.03 |

≤±0.05 |

≤±0.02 |

≤±0.03 |

≤±0.03 |

|

Segment Positioning Error(mm) |

≤±0.03 |

≤±0.03 |

≤±0.02 |

≤±0.03 |

≤±0.03 |

|

Brazing Capacity(pc/h) |

150-500 |

180-550 |

150-500 |

140-550 |

180-550 |

|

Segment Size(L*T*H)(mm) |

30/50×1.8/6×7/35 |

30/45×2.5/12×7/40 |

30/50×1.2/6×7/35 |

22/45×2/12×7/40 |

30/45×2.0/10×7/40 |

|

Rabbet of the Blade(mm) |

≥0.3 |

≥1.0 |

≥0.3~0.03 |

≥1.0 |

≥1.0 |

|

Thickness of the Blade(mm) |

≥0.8 |

≥1.8 |

≥1.0 |

≥1.8 |

≥1.8 |

|

Air Pressure(mpa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

Hydraulic Pressure(mpa) |

≥0.2 |

≥0.2 |

≥0.2 |

≥0.2 |

≥0.2 |

|

Power(w) |

2500 |

2500 |

1300 |

1300 |

500 |

|

Water consumption(m³/h) |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

|

Weight(kg) |

680 |

700 |

230 |

250 |

400 |

|

Size(mm) |

170×140×220 |

170×140×220 |

1150×980×1660 |

1150×980×1900 |

1150×980×1900 |

Processing

Loading