Vertical Type Bevel and Straight Side Stone Polishing Machine For Irregular Shaped Edge

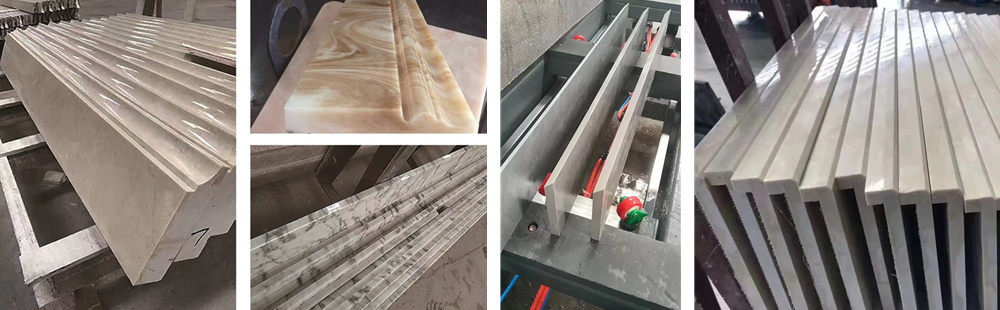

This Granite marble polishing machine is used to polish the straight edge and 45 ° bevel, slot and polish inside a slot of stones. Skirting,planning thickness and polishing for various irregular shaped edge (such as rounded edge, French edge, ogee, etc,) are also within the working range of this stone edge polishing machine.

Item No.:

DZP-9

DZP-11

- Haineng

- Fujian

- 25 days

- 10 PCS Per Month

- Information

Bevel and Straight Side Stone Polishing Machine For Irregular Shaped Edge

Product Introduction

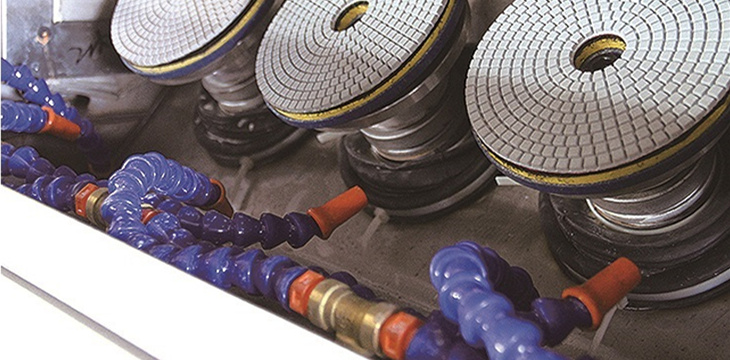

This Granite marble polishing machine is used to polish the straight edge and 45 ° bevel, slot and polish inside a slot of stones. Skirting,planning thickness and polishing for various irregular shaped edge (such as rounded edge, French edge, ogee, etc,) are also within the working range of this stone edge polishing machine. The polishing wheel works in a way that interchanges snailed dish ( attached with fiber polishing disc with abnormality wheels(electroplate/sintering/ resin wheels), which is convenient for assembling/disassembling. Processed stones have high glossiness (lighter than the slab face)consistent angles and lines. The machine has a low rate of malfunction, and the operating of the machine is easy to learn, All of these makes it a second to none type of machine for a stone deep processing factory.

Technical Parameters

Type | Unit | DZP-9 | DZP-11 |

Working width | mm | 100-2000 | 100-2000 |

No.of polishing wheel | pcs | 9 | 11 |

Working speed | m/min | 0.8-5 | 0.8-5 |

Gross power | kw | 30.7 | 36.7 |

Gross weight | kg | 3000 | 3500 |

Overall size (L*W*H) | mm | 6500×1300×2000 | 7500×1300×2000 |

Remark |

|

polishing; 4×Front bevel4. All manual

|

6×Straight edge polishing; 4×Front bevel +1×Back bevel All manual |

Processing