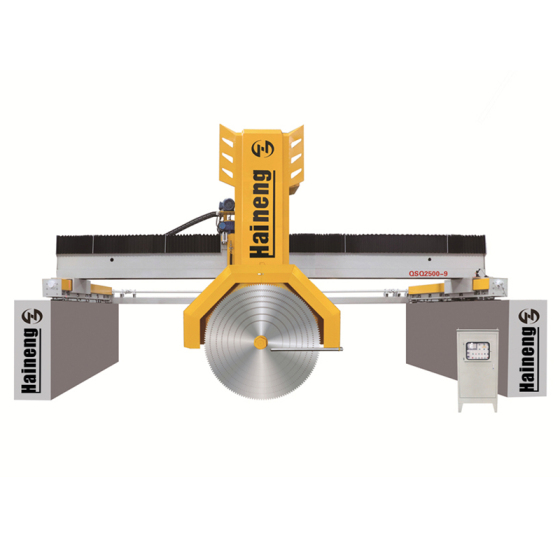

5 Axis CNC Heavty-duty Mono Block Marble Stone Bridge Saw

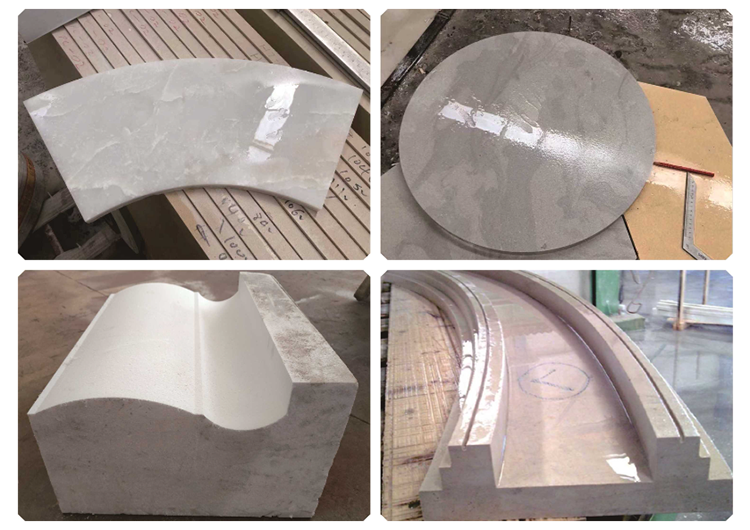

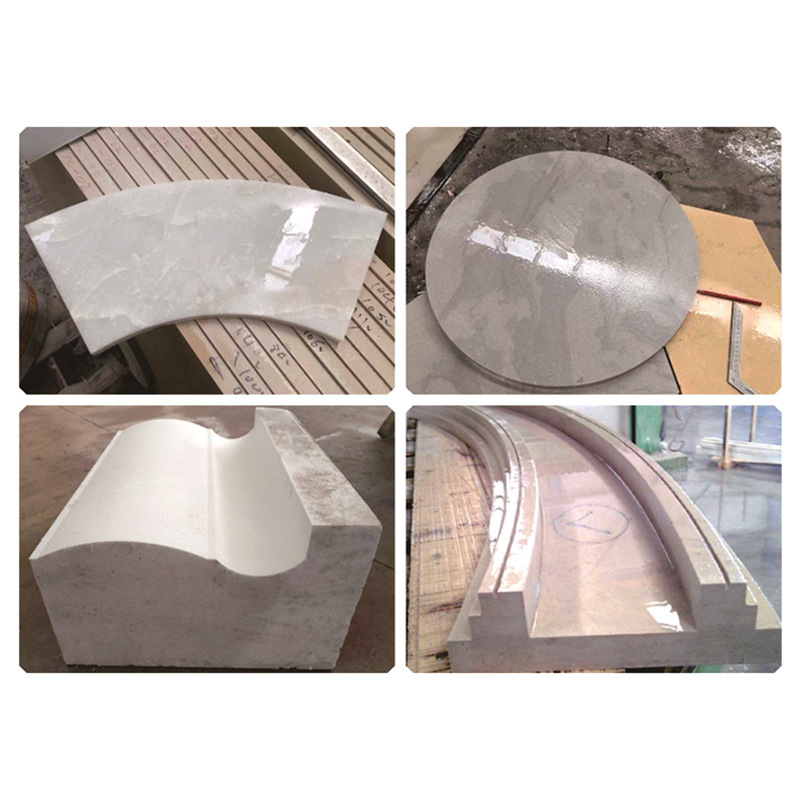

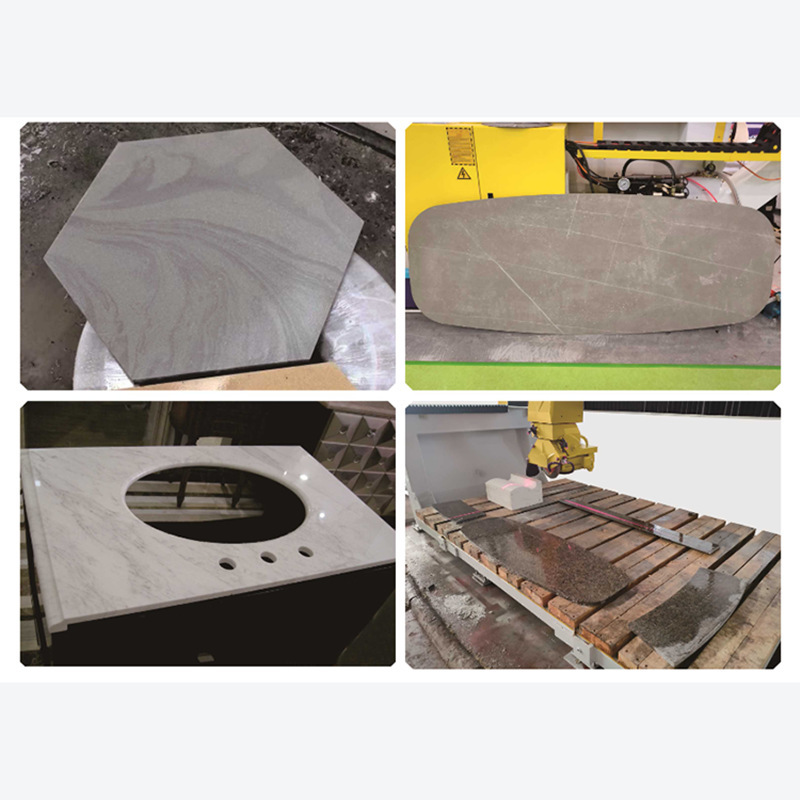

5 axis CNC bridge saw Machine are suitable for slab, tile, marble, artificial stone, granite and other building materials of special-shaped edge or multi-function cutting, is the most suitable for special-shaped cutting factory deep processing equipment.

Item No.: HTQ500GL-1

- Haineng

- Fujian

- 25 days

- 15 PCS per month

- Information

- Video

5 Axis Heavty-duty Mono Block Marble Stone Bridge Saw

Product Features

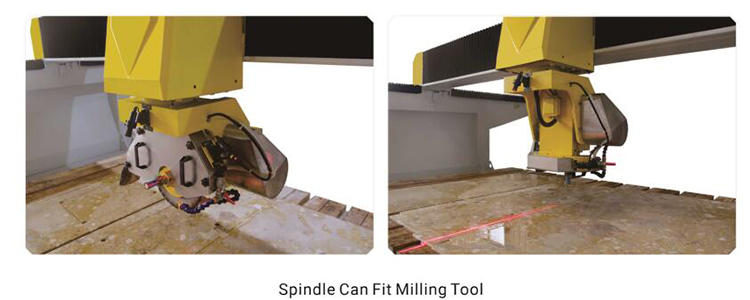

The 5 axis bridge saw Saw is cnc Controlled bridge sawing machine with (5) interpolated axes (X, Y, Z, C,A) for the processing of marble, granite or other natural and engineered stones.

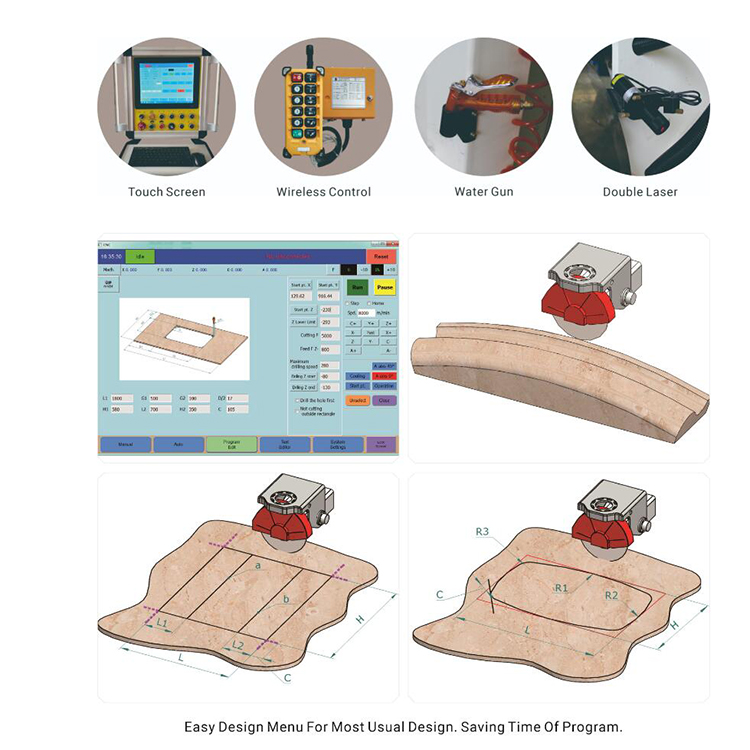

5 Axis Bridge Saw is supplied with a touch screen of easy and intuitive use to CNC software ( CAD CAM) cutting and cuts and movement. Machine can read dxf file of template measurement.

It is possible to execute linear shaping.

1.0° to 360° head rotation and 0° to 90°head tilting.0°-85° table tilting

2.Mono frame structure. Full machine can be loaded inside 20 GP container,So it is easily installment.

3.Mono-axial positionin

g for bridge transaction with servo motor

4.So it is easily installment.Mono-axial positioning for bridge transaction with servo motor.

5.Wifi Connection for the the machine.The software is free updated everyear .The technician can give remote service and training support.

6.Machine with camera can monitor the machine working and service support.

7.Machine will milling tools in the center of spindle, the variable rpm rotating speed.

Technical Data

Type | Unit | HTQ500GL-1 |

Mode of control |

| CNC |

Programming Method 2 |

| CAD |

Main motor power | kw | 18.5 |

Speed |

| 0-4500 |

Stroke of X axis | mm | 2100 |

Stroke of Y axis | mm | 3500 |

Z axis stroke | mm | 500 |

Stroke of axis C | n | 0-360 |

Stroke of axis A | n | 0-90 |

Maximum tilt angle of workbench | n | 0-85 |

Size of work table | mm | 3200×2000 |

Total power | kw | 33 |

Gross weight machine | kg | 5000 |

Installation dimension | mm | 5800×3200×3800 |

Note: The machine adopts linear rack and ball screw, helical teeth, high precision planetary reducer, servo system and other moving parts.

Processing