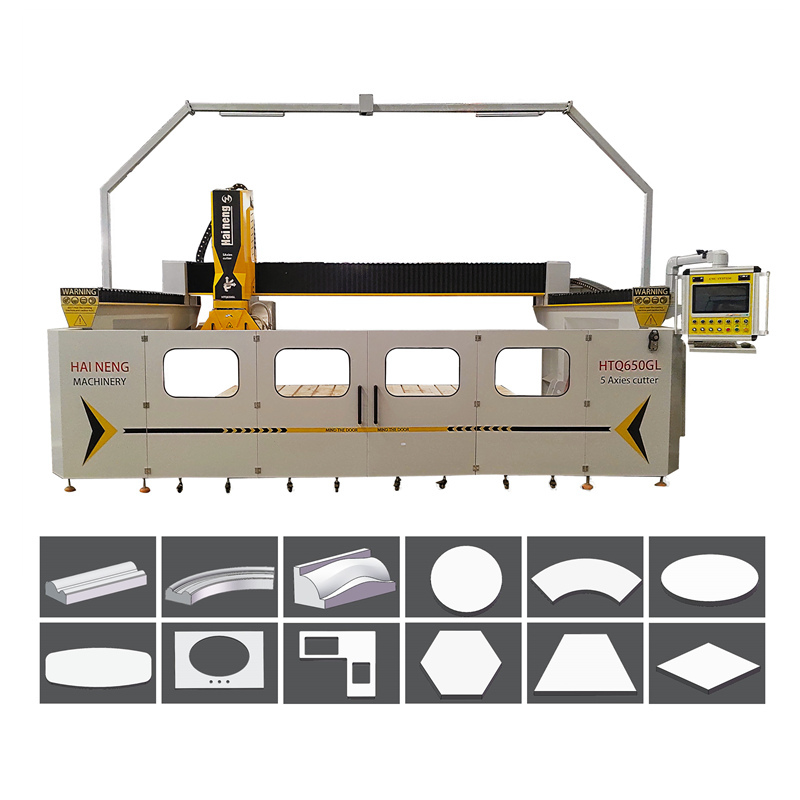

5 AXIS CNC (Heavy Duty) Monblock Stone Bridge Saw Machine

This machine is a multi-functional intelligent CNC bridge stone cutting machine.This machine can cut specifications board, at any Angle, any direction cutting, chamfering, cutting round, oval.

Item No.:

HTQ500GL

HTQ700GL

- Haineng

- Fujian

- 25 days

- 10 PCS Per Month

- Information

- Video

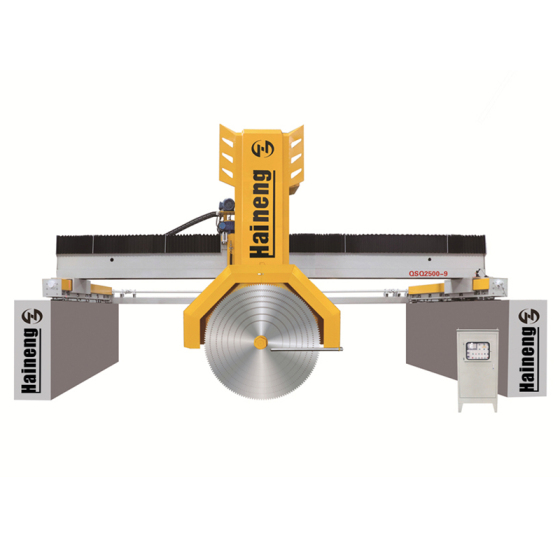

5 AXIS CNC (Heavy Duty) Monblock Bridge Saw

This series of models are suitable for slab, tile, marble, artificial stone, granite, cement products and other building materials of special-shaped edge or multi-function cutting, is the most suitable for special-shaped cutting factory deep processing equipment.

Product Introduction

This machine is a multi-functional intelligent CNC bridge stone cutting machine, operating system is my company in the import of five axis CNC on the basis of the development of their own, simple and easy to learn, to solve the problem that only high education to understand the use.

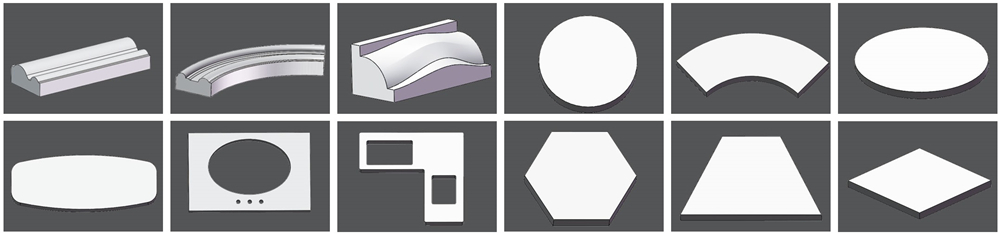

Mono-Block Stone Machine can cut specifications board, at any Angle, any direction cutting, chamfering, cutting round, oval, horse’s belly edge shape, fan,polygons, form various shapes, such as the grid lines, lines, slash groove, contour lines and contour arc line, saw blades(and the workbench Angle) at any Angle between 0-90 degrees cutting, machinable column, column caps, flower POTS and other form. The machine head is equipped with milling cutter device (optional), when rotated to 0 degrees (milling cutter into 90 degrees), can be used as CNC machining center, on the stove, wash the basin hole, tap hole, guide sink, four sides of the milling and polishing(installed on the grinding wheel), straight line, curve, multi-level curve can be.

5 AXIS CNC (Heavy Duty) Bridge Saw Machine adopts high-end water-cooled special motor, the speed is as high as 6000 RPM, the cutting speed is fast, the edge is smooth, neat, no edge collapse (Angle). The operation is simple and intuitive, set up intelligent fast, dumb touch interface, two or three data automatically generated graphics, a key to start the automatic processing. The fuselage adopts integral rigid welding structure, fastening and durable, convenient loading and shifting, and occupies a small area. Full servo motor drive, efficient, accurate, stable, and affordable (only the price of high-end ordinary infrared), is the market requirements continue to improve, the stone processing factory's good helper and profit generator!

Technical Parameters

TYPE | Unit | HTQ500GL | HTQ700GL |

Blade Diameter |

| 350-500 | 350-700 |

Mode of control |

| CNC | CNC |

Programming Method 2 |

| CAD import | CAD import |

Main motor power | kw | 18.5 | 22 |

Speed |

| 0-6000 | 0-6000 |

Stroke of X axis | mm | 3800 | 3800 |

Stroke of Y axis | mm | 2400 | 2400 |

Z axis stroke | mm | 350 | 500 |

Stroke of axis C | n° | 0-360° | 0-360° |

Stroke of axis A | n° | 0-90° | 0-90° |

Maximum tilt Angle of workbench | n° | 0-85° | 0-85° |

Size of work table | mm | 3600×2200 | 3600×2200 |

Total power | kw | 29.5 | 33 |

Gross weight | kg | 4800 | 5000 |

Overall dimensions | mm | 5800×3400×3400 | 5800×3400×3600 |

Processing